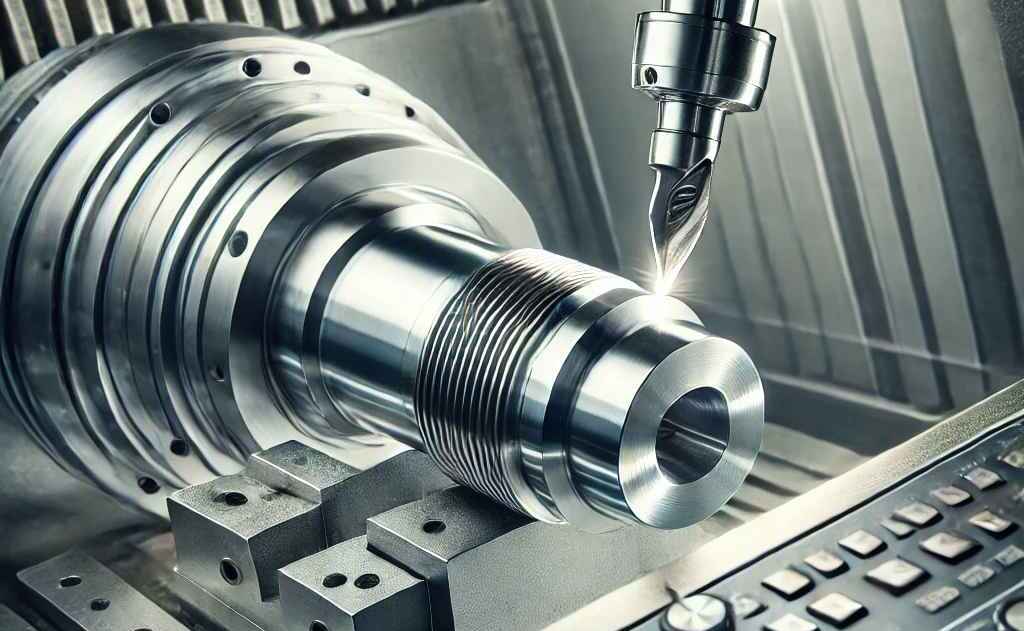

| Manufacturing Process | Injection Mold Making Service & Plastic Injection Molding Service |

| Parts Material | PA66+30%GF, PP, PS |

| Mold Type | Production Tooling |

| Application Industry | Personal Care |

| Surface Treatment | Exterior parts: Spray painting Buttons: Electroplating & Silk-screen printing |

| Tolerance(Accuracy) | 0.03mm |

Notes:

We have pre-market confidentiality agreements with all of our customers. All the cases you see have been communicated with our clients. We have mosaiced some sensitive information. All the pictures are taken from FirstMold’s internal shooting, thanks for your support and cooperation~

Comprehensive Testing and Quality Assurance: Through precise mold design and thorough testing, we guaranteed the product’s quality, addressing the dynamic balance.

Partnerships · Privacy Policy · Terms and Conditions · Sitemap · Copyright 2025 © First Mold(2011-2025). All Rights Reserved.